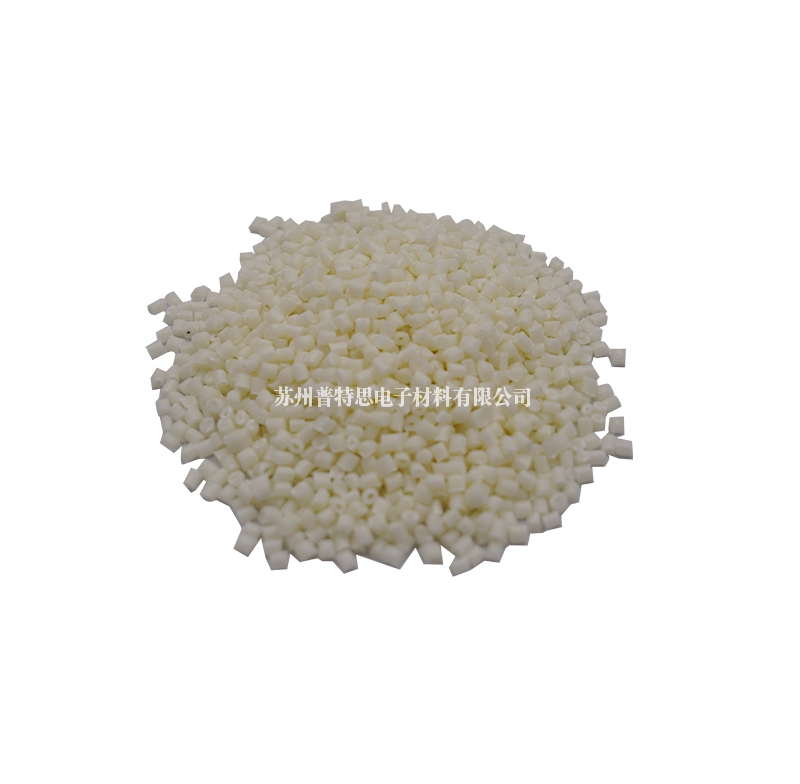

PPS polyphenylene sulfide (PPS) is a member of the polyarylsulfide family. PPS was first discovered in the 1980s. The general PPS material color is yellow or off white, known as one of the six major engineering plastics. With the continuous improvement of material requirements, PPS materials have become a huge amount of engineering plastics in recent years. The long-term use temperature of PPS material products can reach 200 ℃, and due to the existence of S atoms, it can reach UL 94V-0 without adding any flame retardant (1.6mm thick); High rigidity, low molding shrinkage and water absorption, and outstanding advantages in chemical stability and electrical properties. However, PPS is brittle and has poor toughness. It often needs to be used with other materials, and can be used in precision instruments, electronics, automobiles, national defense, petrochemical and other fields.

In order to improve the brittleness and processing difficulty of pure PPS materials, we usually add filler materials to PPS materials. We all know that fiber has high modulus and strength. By adding fibers into PPS materials, the brittleness of pure PPS materials can be effectively improved. When impacted by external forces, fiber materials can absorb a large part of the stress, thus improving the impact strength and heat resistance of PPS composites. At present, carbon fiber, glass fiber and aramid fiber can be used as filler fibers.

In addition to fiber filling and modification of pure PPS materials, polymer materials can also be mixed with PPS materials. Different from inorganic fillers and reinforcing fibers, polymers have different molecular structures and often have more abundant surface groups and physical and chemical properties. Blending PPS with other polymers by appropriate methods to prepare composites can greatly improve the impact strength of materials, expand the application range of materials in some fields, and greatly reduce their production costs. In composite materials, the interface bonding of two-phase or multiphase polymers is very important. The general compatibility is affected by solubility parameters, viscosity, polarity, surface tension and processing temperature. When the compatibility is good, the excellent performance of each phase can be comprehensively exerted.